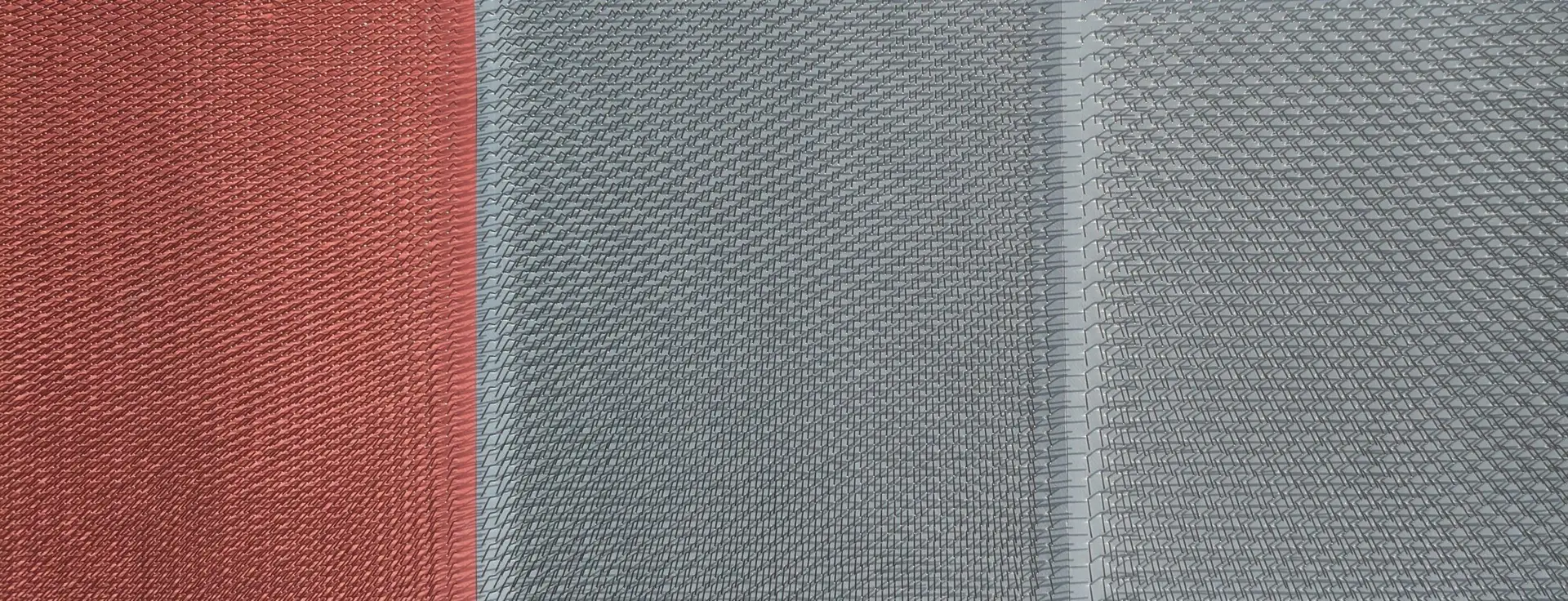

When choosing the right needle density for your drum carder, it’s important to know what types of fibers you want to process. Needle density is measured in teeth per inch (TPI) and determines how fine or coarse the wool will be carded. Here is an overview of the different densities and their best applications:

120 TPI – For Fine Wool

The 120 TPI carding cloth is designed for processing fine wool types such as Merino or Alpaca. This high needle density allows fine fibers to be carded without breaking, resulting in a soft and even batt. This is the best choice when working with luxurious, soft wool. This cloth is not suitable for coarse wool, as the high density can damage the thicker fibers.

72 TPI – The Versatile Option

With a needle density of 72 TPI, you can do almost anything. This is the most versatile option and works very well for most sheep’s wool, for example, wool from the Frisian Milk Sheep. It offers a good balance between carding fine and coarse fibers, making it suitable for a wide variety of wools. This carding cloth also performs well if you occasionally work with Merino or Alpaca.

54 TPI – For Coarse Wool

The 54 TPI carding cloth is perfect for carding coarse wool types, such as wool from the Drenthe Heath Sheep. If you’re working with rougher, thicker fibers, this density is the best choice. The lower needle density separates the coarse fibers effectively without too much resistance, resulting in a thick, sturdy batt.

Conclusion

For those looking for a versatile drum carder that can work with a wide range of wool types, 72 TPI is the best choice. With 72 TPI carding cloth, you can process both fine and slightly coarser fibers with good results. However, if you specifically work with very fine or very coarse fibers, consider the respective 120 TPI or 54 TPI options for optimal performance. Still have questions? Feel free to contact us.